Corrosion control and protective coatings management must be addressed through professional assessment, planning, and execution. The challenge is to provide successful and cost-effective solutions to difficult problems. Our program approach answers the challenge. The primary business objectives of an engineered program are to:

- Preserve the physical assets and their integrity

- Reduce the life-cycle costs of coatings systems

- Ensure public safety by preventing catastrophic failure of the infrastructure

- Ensure regulatory compliance

- Prevent costly premature failures

- Ensure operational integrity and minimize any impact to operations

The goal is to maximize the return on dollars invested in corrosion control and protective coatings systems, including maintenance. Corrosion and coatings problems can often be linked to the original construction. For this reason, a corrosion control and protective coatings management program should encompass effective design for construction modifications, as well as periodic maintenance.

The essential technical elements of a successful program are:

- Effective design for construction & maintenance

- Knowledge-based standards

- Requirements-based specifications

- Material testing & qualification (the right product for the project)

- Accurate assessment of facility service conditions

- Trained & qualified personnel

- Quality assurance & control (in-process inspections)

- Data management & information systems

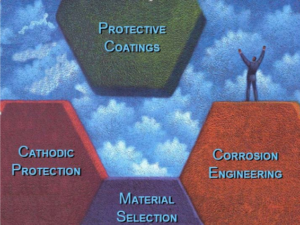

Four Elements of Control

The absence of any one technical element increases the risk of failures that negatively impact costs and operations. Commonly, facility owners focus on selecting the “right paint” without regard to other equally important issues. In addition, material and process decisions are rarely made centrally, as they would be under an engineered program. This can lead to the repetition of errors and the management failure to consistently implement positive lessons learned.

CONSULEX® offers professional corrosion control engineering and protective coatings technical services with a focus on total program support. Our program approach starts with a baseline audit and analysis of the client’s current status against their goals and objectives for a corrosion control plan. This is followed by an action plan that covers the four major organizational elements of the program model: engineering, support, operations and logistics.

The action plan is customized to individual client needs determined by the baseline assessment and the desired implementation structure. At CONSULEX®, we are committed to the success of your corrosion control and protective coatings management program. Our approach is comprehensive, structured, professional, knowledge-based, value-added and customized to the client.